R&D and Quality Control

From concept to mass production — our integrated R&D and QC systems ensure every eBike meets the highest industry standards.

Innovation-Driven R&D Team

- Cross-Disciplinary Expertise

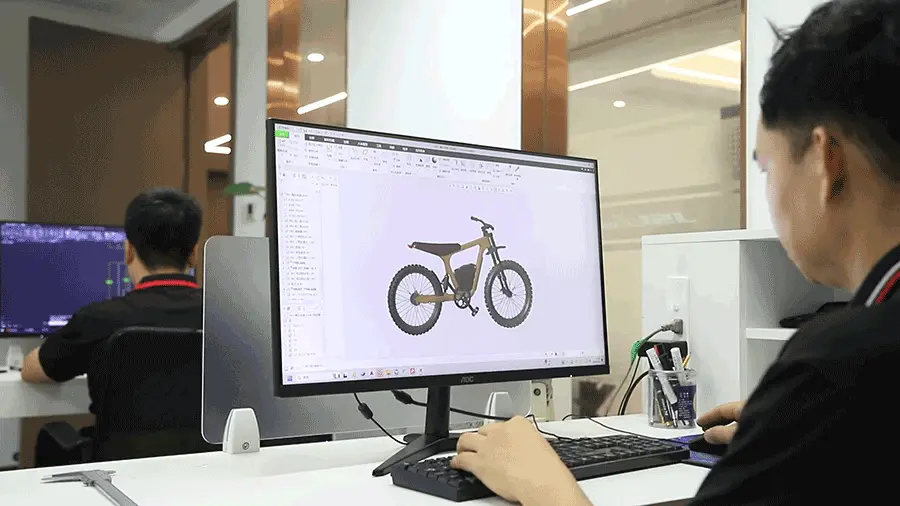

Our R&D team includes 20 seasoned professionals across mechanical design, electronics, and materials science — ready to handle complex customization demands. Advanced Tools & Tech

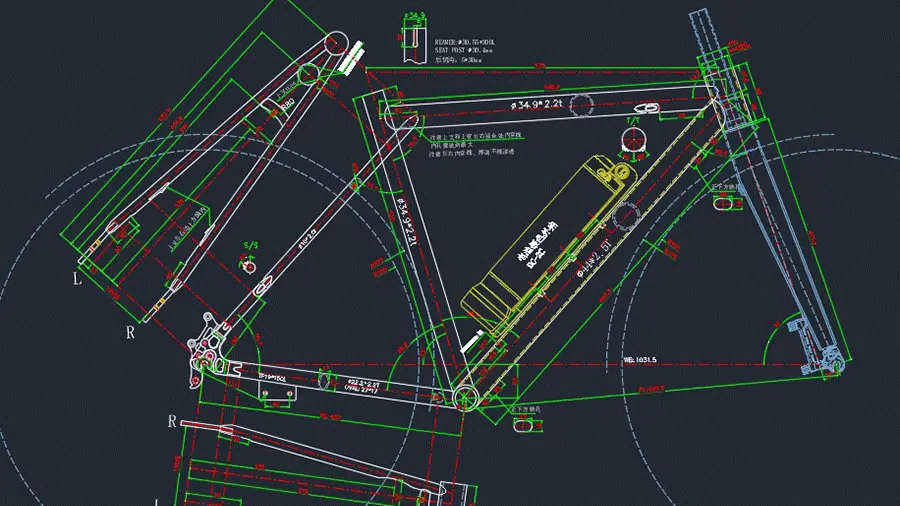

We utilize CAD, SOLIDWORKS, 3D printing, and simulation systems to accelerate development and ensure precision at every stage.Customer-Centric Customization

Whether it’s special frame geometry, integrated sensors, or unique branding elements — we tailor product development to your market’s needs.Process-Integrated Quality Thinking

Quality assurance begins at the design stage, with rigorous controls applied throughout R&D to avoid downstream issues.

From Idea to Sample — Our R&D Steps

1. Conceptual Design

Based on the requirements, our R&D engineers create multiple concept proposals. We evaluate them for performance, manufacturability, and cost-efficiency to ensure the best balance of form and function.

2. Engineering & Technical Validation

We use CAD, SOLIDWORKS, and simulation tools to design frame geometry, electronic systems, and mechanical integration. BOM (Bill of Materials) and core components are finalized during this phase to ensure reliable sourcing and quality.

3. Prototype Development

Functional prototypes are built using in-house 3D printing, CNC machining, or pilot production lines. Each prototype undergoes basic road tests and internal lab tests to validate structural strength, performance, and user experience.

4. Optimization&Finalization

Based on testing results and client feedback, we fine-tune design details. This may involve modifying weld geometry, motor controller settings, or accessory integration — all before final tooling or bulk production begins.

Integrated Quality Control At Every Stage

Strict Quality Standards

All processes comply with ISO 9001 and EN15194 standards, with documentation and traceability for each unit.In-Process & Final Testing

Products undergo inspection not only at the end but at critical production milestones — ensuring zero-compromise delivery.

Advanced Testing Equipment in Our QC Lab

Ready to Bring Your Ebike Project to Life?

Looking for a reliable OEM partner with strong R&D capabilities and uncompromising quality control?

Let’s build your next electric bike — together.

CE / TUV / UL / ISO9001